Specification

- Foaming times: 3-40 times

- Width: 500-2000mm

- Thickness: single layer 0.1-15mm; multi-layer 15-200mm

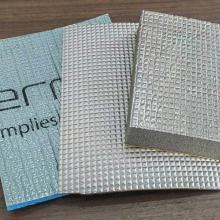

- Surface treatment: calendaring, embossing or corona treatment.

- Colour: black, white, grey, colourful, etc., can be customized.

IXPE foam material(Ionizing Radiation Crosslinked Polyethylene) , i.e. Electron Beam Radiation Crosslinked Polyethylene Foam, is a kind of high molecular weight polyethylene resin as the main raw material, through the addition of appropriate amount of blowing agent, stabilizer and other functional additives, after mixing and homogeneous, the use of extruding molding technology to prepare the initial billet, and then after the Irradiation treatment with high-energy electron beam generated by special electron accelerator makes the polyethylene molecular chain cross-linking reaction and forms the closed-cell foam with three-dimensional network structure.

Features

- environmental protection and non-toxic: IXPE foam production process does not use harmful substances, and the product itself is odorless and pollution-free, in line with international environmental standards.

- excellent physical properties: due to cross-linking, IXPE foam has good mechanical strength and heat resistance, while maintaining excellent flexibility and elastic recovery.

- anti-static properties: some IXPE products can be added to conductive fillers and antistatic agents, so that it has a stable anti-static property, surface resistance and volume resistance can be controlled within a specific range.

- Sound and heat insulation: closed cell structure makes IXPE foam has excellent thermal insulation performance, as well as good sound absorption and noise reduction effect.

- Waterproof and breathable: IXPE foam can effectively prevent moisture penetration, while allowing air and other gases to pass through, which is conducive to the elimination of moisture and maintain a dry environment.

- Easy processing and customization: IXPE foam is easy to cut, stamping, composite and other processing methods, according to different application requirements can be designed into a variety of shapes and thickness of the product.

Application

- Packaging materials: Because of its good buffer performance, it is widely used in the anti-seismic packaging of precision instruments, electronic products, high-grade gifts and other products.

- construction materials: as floor cushioning materials, wall thermal insulation layer, roof waterproof materials, etc., it plays the role of energy saving and thermal insulation, sound insulation and shock absorption in construction projects.

- automotive interior: IXPE foam is used in automotive roof, floor, seat padding and other parts to provide a comfortable riding environment and effective NVH (noise, vibration, and harshness) control.

- Home furnishings: such as mattresses, mats, yoga mats, children's crawling mats, etc., to take advantage of its comfortable, safe, and hygienic characteristics.

- sports and leisure: outdoor sports equipment, protective layer of water sports equipment, and stadium floor covering materials, etc.

- Other industrial uses: including insulation for heating and cooling equipment, protective gear for the healthcare industry, craft production, and aerospace are widely used.