Specification

- Foaming times: 3-40 times

- Width: 500-1800mm

- Thickness: single layer 2-12mm; multi-layer 12-200mm

- Surface treatment: calendaring or corona treatment.

- Color: black, white, grey, color, etc., can be customized.

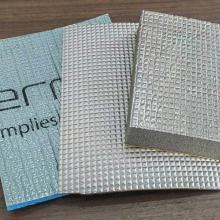

XPE form material, known as Chemically Crosslinked Polyethylene (XPE for short), is a foaming material with high-density or low-density polyethylene resin as the main raw material. It is through the introduction of chemical cross-linking agent between the polyethylene molecular chain, cross-linking reaction occurs under specific conditions, so that the original linear polyethylene molecular structure to form a three-dimensional mesh structure, and then mixed with the blowing agent and under high temperature and high-pressure foaming treatment, and ultimately produced with independent closed-cell structure of the foam.

Features

- Excellent cushioning performance: XPE foam is a semi-rigid foam, with excellent cushioning and shock absorption performance, even after a strong impact can still maintain the original physical properties, effectively protect the packaging from damage, so it is widely used in precision instruments, electronic equipment, and semiconductor products cushioning packaging.

- Good formability: XPE foam has good heat resistance and easy to form, can be processed into various shapes and sizes according to the needs of the product, such as gaskets, rolls, blocks, etc., suitable to produce sports protective equipment, leisure and recreational products, as well as other special requirements for the shape of the application field.

- Thermal insulation: Because of its closed cell structure, XPE foam has excellent thermal insulation performance, which can effectively prevent heat transfer, so it is used as thermal insulation material in the fields of housing construction, automobile interiors and so on.

- waterproof and moisture-proof: XPE foam has good waterproof and moisture-proof performance, does not absorb water and is not easy to reduce the performance of moisture, to help maintain a stable use of the environment.

- Environmental protection and harmless: XPE foam production process using environmentally friendly technology, the material itself is non-toxic, odorless, non-polluting, recyclable, in line with modern industry and life on the requirements of green materials.

Application

- Packaging industry: used for all kinds of high-end commodities, precision instruments, electronic products, works of art, etc., internal cushioning packaging and external protective cover.

- Automobile interior: used as sound insulation, heat insulation and shock absorption parts of vehicle interior, such as car roof, door panel filling, seat cushioning layer, etc.

- building materials: used as thermal insulation materials for building walls, floors and roofs, and as pipeline thermal insulation wrapping layer.

- Sports protection: as mats for sports grounds, protective covers for sports equipment, and linings for outdoor equipment.

- Children's toys and daily necessities: due to its safe, non-toxic and soft and comfortable characteristics, it is often used in baby crawling mats, yoga mats, mattresses and all kinds of daily consumer goods.