With food safety increasingly in the spotlight, liquid food packaging demands exceptionally stringent performance from base materials. Leveraging advanced papermaking technology and deep industry expertise, Bofeng New Materials introduces high-performance liquid packaging base paper. This product serves as the core substrate for aseptic composite cartons (e.g., Tetra Pak, Combibloc), specifically designed for packaging milk, juice, beverages, and various liquid foods. It functions not merely as a container but as a critical barrier safeguarding the safety, nutrition, and freshness of liquid foods throughout processing, transportation, and storage.

Product Features

- Exceptional Strength and Processing Performance

- High Strength Characteristics: Possesses extremely high dry and wet tensile strength, tear resistance, and internal bonding strength, ensuring minimal paper breakage on high-speed filling lines and guaranteeing smooth, efficient production.

- Superior Creasing and Formability: The paper's uniform fiber structure provides excellent stiffness and flexibility, facilitating precise creasing and folding. This results in final packaging boxes with a crisp, aesthetically pleasing shape.

- Exceptional Cleanliness and Hygiene Safety

- Pure Raw Materials: Manufactured from 100% virgin wood pulp or specialty pulp meeting international food contact standards, free from fluorescent whitening agents to ensure raw material safety.

- Controlled Production Environment: Produced in a fully enclosed, clean production system that effectively controls microorganisms and impurities. Base paper undergoes rigorous hygiene testing before shipment, meeting stringent requirements for aseptic packaging.

- Superior Laminating and Barrier Foundation

- Ideal Surface Properties: Features a smooth, fine paper surface with uniform pore structure and excellent surface absorbency, enabling perfect lamination with barrier materials like PE plastic or aluminum foil without delamination or bubbles.

- Robust substrate function: Serves as the “backbone” of composite materials, providing a stable and reliable base for subsequent processes like film lamination and metallization. Together, they form a multi-layer barrier system resisting oxygen, moisture, and light.

- Excellent Chemical Resistance and Compatibility

- Acid and Oil Resistance: Withstands weak acid erosion from liquid foods like juices and yogurt, preventing packaging strength degradation or deformation caused by content permeation.

- Sustainability and Environmental Friendliness

- Derived from Renewable Resources: Primarily made from wood pulp sourced from sustainably managed forests, it is a renewable and eco-friendly material.

- Highly Recyclable: The paper-based composite packaging structure facilitates recycling and reuse, aligning with global green circular economy trends.

Primary Applications

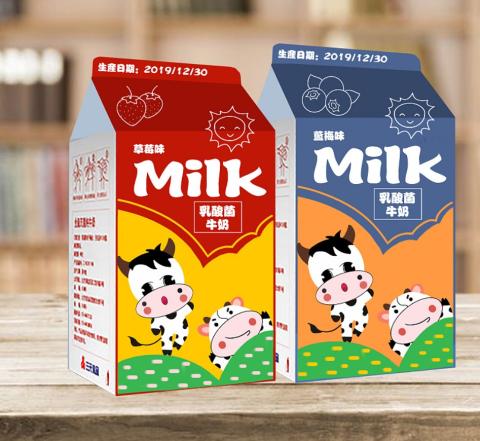

Bofeng Liquid Packaging Paper is the core material for manufacturing various aseptic liquid food cartons, primarily used in:

- Dairy Packaging: Single-use aseptic cartons for UHT milk, yogurt, cream, dairy beverages, etc.

- Juice & Beverage Packaging: Aseptic paper-based composite packaging for concentrated juices, 100% pure juices, plant-based protein drinks, tea beverages, and similar products.

- Other Liquid Food Packaging: Packaging for soups, sauces, alcoholic beverages, liquid nutritional products, and other liquid foods requiring aseptic or ambient storage.

- Mainstream Packaging Systems: Compatible with processing requirements for global aseptic packaging systems including Tetra Pak, SIG Combibloc, and Pure-Pak.

Choosing Bofeng Liquid Packaging Paper means choosing safety, reliability, and efficiency. Let us be your most trusted partner in the supply chain, delivering freshness and health to consumers worldwide!

Email: Jason.zhan@bofmat.com