Specification

- Grammage: 60-100gsm

- Filter efficiency: 99.5%-99.9995%

- Waterproofness: 5500pa。

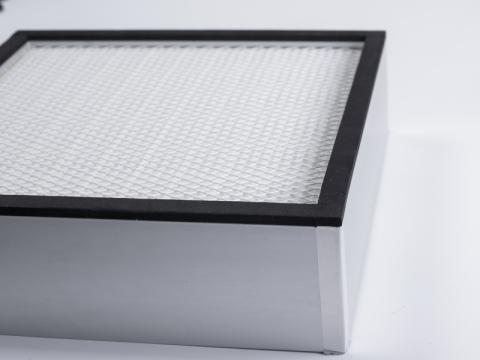

Glass fiber filter paper is a kind of highly efficient filter medium made of ultra-fine glass fibers as the main raw material through a special process. This filter material is widely used in the field of air and liquid purification. Its core part is a three-dimensional structure interwoven by very fine glass fiber filaments, which has high porosity and surface area, thus realizing high efficiency interception and separation of tiny particles.

Features

- High filtration efficiency: Due to the extremely fine diameter and uniform distribution of glass fibers, it can effectively capture particles of various sizes, including sub-micron particles, and is therefore widely used in HEPA (High Efficiency Particulate Air) and ULPA (Ultra High Efficiency Particulate Air) filters, where it can achieve a filtration efficiency of 99.97% or even higher.

- Large dust capacity: glass fiber filter paper has a high dust capacity and can hold a large amount of dust and other particles within its fiber network, maintaining a long service life.

- Small resistance: compared with other types of filter materials, glass fiber filter paper reduces air flow resistance because of the complex zigzagging of the air flow path, which enables the air to pass smoothly under lower pressure drop and reduces energy consumption.

- High mechanical strength: after wet forming process, the glass fiber filter paper has good resistance to stretching, tearing and folding, to ensure stability in the process of use.

- Good chemical stability: glass fiber has excellent acid and alkali resistance and high temperature resistance, not easily affected by most chemicals, suitable for a variety of working conditions.

- Composite protective layer: some high-grade glass fiber filter paper will be compounded with synthetic fiber or natural fiber on both sides or one side as a protective layer, which not only enhances the overall structural strength, but also improves the durability of the filter paper.

Applications

- Air purification: glass fiber filter paper is a core component of all types of air purification equipment, such as domestic and commercial air conditioning systems, clean rooms, hospital operating rooms, semiconductor, and microelectronic industries, etc., where a high degree of clean air is required.

- Liquid filtration: In industrial production processes, such as pharmaceuticals, food and beverage, chemical industry, etc., composite glass fiber filter membranes are used for precision filtration of liquids to remove particulate contaminants therein and ensure product quality.

- Environmental protection: in waste gas treatment facilities, used to capture solid particles in harmful gas emissions, reduce environmental pollution.

- Laboratory research: Highly efficient glass fiber filter paper is also used in many precisions experimental operations in laboratories to prevent sample contamination.