PHA injection molding material is PHA material specially designed and manufactured for the injection molding process. After special treatment or modification, these materials can better adapt to the physical and chemical properties required in the injection molding process, such as melt flowability, thermal stability, etc., so as to ensure the quality of the final product and production efficiency.

Features

- good biodegradability: it can be completely decomposed into carbon dioxide and water by microorganisms in the natural environment.

- Excellent biocompatibility: non-toxic and harmless to human body, suitable for medical field.

- Adjustable mechanical properties: by changing the synthesis conditions or blending with other materials, different hardness and strength can be obtained.

- Good processing performance: the optimized PHA material, while maintaining its excellent properties, also has good fluidity and low viscosity, suitable for a variety of complex injection molding process.

- Environmentally friendly: the entire production and use cycle of environmental pollution is small, in line with the concept of sustainable development.

Applications

- Packaging industry

- Food packaging: used to make disposable tableware, food containers, etc., both safe and environmentally friendly.

- Daily necessities packaging: such as cosmetic bottles, shampoo caps and so on.

- Medical and Health Care

- Surgical sutures: Utilizing PHA's good biodegradability and biocompatibility, it is made into sutures that do not need to be taken out by secondary surgery.

- Tissue engineering scaffolds: as a support structure for cell growth, to promote tissue regeneration.

- Agriculture

- Mulch: Replacing traditional PE mulch to reduce white pollution.

- Slow-release Fertilizer Carrier: wrapping up the fertilizer, slowly releasing nutrients and improving the utilization rate.

- Automotive Industry

- Interior parts: non-structural parts such as dashboards, door panels, etc., to reduce the weight of the car body and reduce carbon emissions.

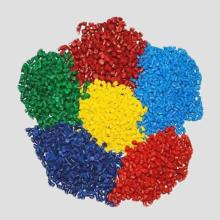

Product Category