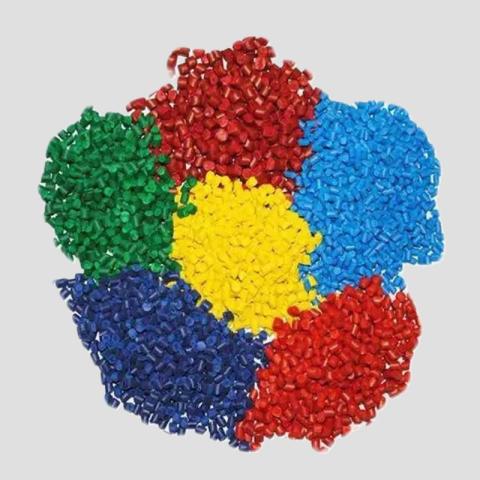

PHA is a natural polymer material synthesized by microorganisms with good biodegradability and biocompatibility, while PHA color masterbatch is a colorant made by mixing pigments or dyes of a specific color with the PHA base material. It is mainly used to add color to other PHA products to meet the aesthetic needs of different applications.

Features

- Environmentally friendly: Since PHA itself is a fully biodegradable material, color masterbatches based on PHA also have the same environmentally friendly characteristics.

- High safety: It is suitable for food packaging and other fields with high safety requirements, and will not cause harm to human health.

- Bright and long-lasting color: through careful selection and proportioning of pigment components, it can ensure that the final product has a bright and stable color performance.

- Good processing performance: easy to mix with other PHA resins, and can be smoothly molded under conventional plastic processing conditions.

- Customizable: the formula can be adjusted according to customer needs to produce products with different color tones and transparency.

Applications

- Packaging industry: used in the manufacture of various types of food containers, bottles and films and other disposable products, not only to ensure the safety and hygiene of the contents, but also to reduce environmental pollution.

- textile and garment: as one of the fiber dyeing raw materials, it helps to produce more natural and comfortable clothing with good visual effect.

- Agricultural mulch film: Utilizing its biodegradable nature to make agricultural mulch film, it can improve crop yield while avoiding the soil pollution problems brought by traditional plastic mulch film.

- Daily consumer goods: such as toys, stationery and other fields are also beginning to try to use this new material to replace the traditional non-biodegradable plastics, in order to respond to the global call for sustainable development.

Product Category