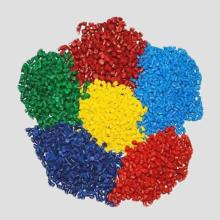

PHA is a natural polymer material synthesized by microorganisms through a fermentation process. It has good biodegradability and biocompatibility, and is widely recognized as one of the ideal alternatives to solve the problem of plastic pollution. PHA sheet material is raw material formulations designed and developed specifically for the production of PHA film or sheet, and these specialties are able to meet the performance requirements of different application scenarios through specific process treatments.

Features

- Environmentally friendly: PHA is entirely from renewable resources and can be rapidly decomposed into carbon dioxide and water in the natural environment, without causing environmental pollution.

- Biocompatibility: Since its structure is similar to human tissue, it is harmless to the human body and suitable for medical and health care.

- Excellent mechanical properties: the modified PHA material has good strength and toughness, and can meet a variety of packaging needs.

- Strong processing adaptability: it can be processed and molded by blow molding, injection molding and other ways, which is convenient for mass production.

- Better heat resistance: Compared with some other biodegradable plastics, PHA has a higher melting point and can be used in a wider temperature range without deformation.

Applications

- Packaging Industry

- Food packaging: disposable tableware and plastic wrap made of PHA are not only safe and hygienic, but also easy to recycle;

- Daily necessities packaging: such as cosmetic boxes, toy bags, etc., the use of PHA material is both beautiful and environmentally friendly.

- Agricultural field

- Mulching: used to replace the traditional PE mulch, which can maintain soil moisture and reduce white pollution;

- Plant nursery containers: made into seedling trays or pots, conducive to the growth of plants, but also convenient for later cleaning.

- Healthcare

- Surgical suture: PHA is very popular as suture material in surgery due to its excellent biocompatibility and controlled degradation rate;

- Drug slow-release carriers: drugs are encapsulated in PHA microspheres to achieve stable release over a long period of time.

- Other aspects

- Electronic product shell: with technological advances, some small electronic devices began to try to use PHA as a shell material;

- Textile fibers: a new generation of PHA-based environmentally friendly textiles has been developed, combining comfort and sustainability.

Product Category