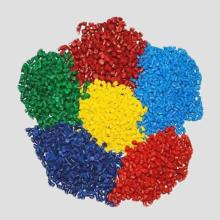

PHA is a natural polymer material produced by microorganisms through the process of fermentation, with good biodegradability and biocompatibility. PHA blown film material refers to the PHA material formulations specially designed for the production of film, which not only maintains the original excellent characteristics of PHA, but also optimized for the problems that may be encountered in the process of film processing.

Features

- environmental protection: as a bio-based material, PHA can be completely degraded to carbon dioxide and water under natural conditions, which is friendly to the environment.

- Mechanical properties: After special treatment, PHA blown film specialties have certain strength and tear resistance while maintaining good flexibility.

- Processing adaptability: In response to the requirements of the film production process, PHA blown film specialties have been adjusted in terms of melt index, crystallinity, etc., to ensure that they can be molded smoothly on standard plastics processing equipment.

- Transparency and gloss: Some of the modified PHA blown film materials are able to achieve high transparency and surface gloss to meet the needs of different application scenarios.

- Barrier properties: For some specific types of PHA, they also have good oxygen and water vapor barrier properties, suitable for food packaging and other areas.

Applications

- Packaging industry: PHA blown film specialties have good mechanical properties and excellent biodegradability, so they are very suitable for the production of disposable plastic bags, cling film and other products.

- Agriculture: PHA blown film can be automatically decomposed at the end of the crop growth cycle, reducing white pollution and contributing to soil health.

- Healthcare: In view of the biocompatibility of PHA material itself, the medical packaging material produced by using PHA blown film specialties can better protect medical devices or medicines, and is harmless to the human body.

- personal care products: such as wet wipes packaging, mask stickers and other products have also begun to try to use PHA blown film to replace the traditional plastic material, not only to ensure the functionality of the product and take into account the environmental requirements.

Product Category