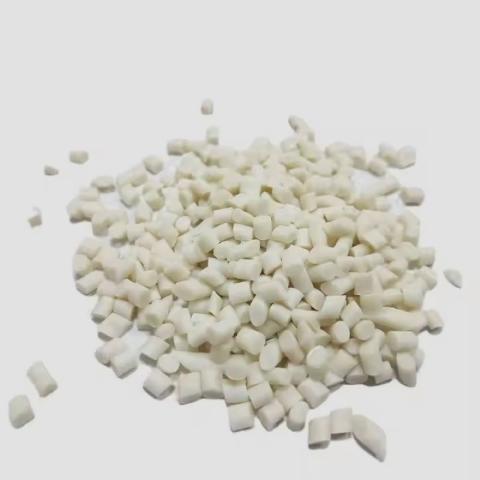

PHA extrusion molding material is PHA material designed and produced specifically to meet the demands of the extrusion molding process. These materials usually need to have good fluidity, thermal stability and certain mechanical strength to adapt to different types of extrusion lines and to ensure the quality and performance of the final product.

Features

- good processing performance: optimized for the extrusion process, improve the melt index and fluidity of the material, easy to process and molding.

- excellent physical and mechanical properties: the brittleness of the original PHA material has been improved through the addition of toughening agents or other modification means, making it more durable.

- Outstanding biodegradability: PHA retains its nature as a bio-based plastic - it decomposes quickly in the natural environment and is environmentally friendly.

- High safety: suitable for the production of food contact materials, harmless to the human body.

- Adjustable color and transparency: by adjusting the ratio of the formula, products with different colors and transparency can be obtained.

Applications

- Packaging industry

- Food Packaging Bags: The film made of PHA extruded special material can be used to replace disposable tableware and cling film made of traditional plastic, which is both environmentally friendly and safe.

- Express packaging materials: with the development of e-commerce, express packaging has become a major source of pollution. The cushioning bubble film and fillers produced by PHA extrusion specialties can effectively reduce environmental pollution.

- Agricultural field

- Mulch film: PHA mulch film can not only meet the heat preservation and moisturizing conditions required for crop growth, but also can be naturally degraded after use to avoid soil pollution.

- Plant seedling trays: small containers used in the germination stage of plant seeds, which can be buried directly into the soil after use without recycling.

- Medical and Healthcare

- Surgical suture: PHA material is widely used as absorbable suture in surgery due to its good biocompatibility and controllable degradation rate.

- Slow-release carriers: By controlling the composition and structure of PHA materials, the slow release of drugs can be realized, which improves the therapeutic effect and reduces the side effects at the same time.

Product Category